Here are some potential advancements that were common in the industry up to 2022:

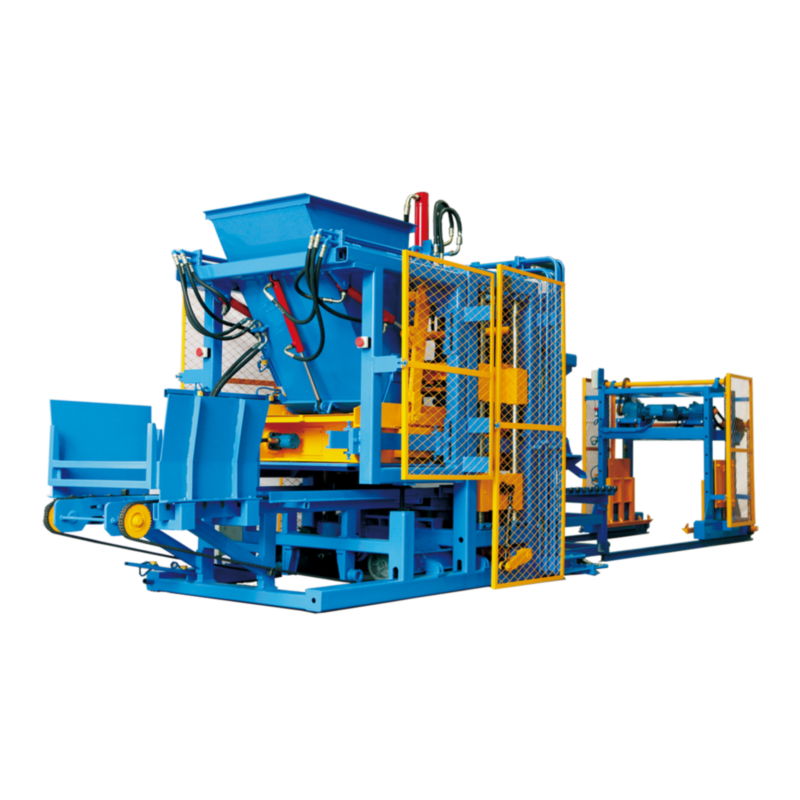

- Automation and Control Systems:

- Advanced automation features, including programmable logic controllers (PLCs) and touch-screen interfaces, enhance the precision and efficiency of cinder block production. These systems allow for easy control, monitoring, and adjustment of various machine parameters.

- Energy Efficiency:

- Manufacturers have been focusing on developing energy-efficient cinder block machines. This includes the use of optimized power systems, energy recovery technologies, and the integration of eco-friendly practices in the production process.

- Vibration Technology:

- Innovations in vibration technology contribute to better compaction of concrete mixtures, resulting in cinder blocks with improved strength and durability. Adjustable and advanced vibration systems allow for customization based on specific project requirements.

- Modularity and Flexibility:

- Modular designs in cinder block machines offer flexibility in terms of production capacity and block sizes. cinder block machine Machines with interchangeable molds and components allow producers to adapt to varying project needs easily.

- Material Optimization:

- Some advancements involve the optimization of raw material usage. This includes innovations in the mixing process, use of alternative and sustainable materials, and improved material handling systems to minimize waste.

- Incorporation of Sensors and Monitoring Devices:

- Sensors and monitoring devices are increasingly being integrated into cinder block machines. These technologies allow for real-time monitoring of production processes, ensuring quality control and minimizing errors.

- Quick Mold Changing Systems:

- Quick mold changing systems reduce downtime between production runs. Machines with efficient mold changing mechanisms enhance overall productivity by allowing producers to switch between different block sizes and shapes rapidly.

- Innovative Demolding Systems:

- Demolding processes have seen improvements, with innovative systems designed to release blocks smoothly without causing damage. This is crucial for maintaining the integrity of the final product.

- Remote Monitoring and Diagnostics:

- Some cinder block machines offer remote monitoring and diagnostics capabilities. This allows operators to track machine performance, receive real-time alerts, and troubleshoot issues remotely, improving overall efficiency and minimizing downtime.

- Advanced Compaction Mechanisms:

- Advancements in compaction mechanisms, such as the use of hydraulic systems, contribute to achieving higher levels of block density. This ensures that the produced cinder blocks meet or exceed quality standards.

- Intelligent Production Planning:

- Some modern cinder block machines are equipped with intelligent production planning features. These systems optimize production schedules, material usage, and energy consumption, leading to more efficient and cost-effective operations.

- User-Friendly Interfaces and Training Programs:

- User-friendly interfaces and comprehensive training programs are becoming standard features. This facilitates easier operation for machine operators and ensures that they are well-trained in utilizing the full capabilities of the equipment.

- Durability and Robust Construction:

- Innovations in machine construction focus on durability and robustness. This includes the use of high-quality materials, reinforced frames, and components designed to withstand the rigors of continuous production.

For the latest information on specific models and their innovations, it is recommended to consult with cinder block machine manufacturers, industry exhibitions, and publications for the most recent developments in the field.

How does the concrete blocks machine cope with variations in ambient conditions during operation?

Concrete block machines are designed to cope with variations in ambient conditions during operation to ensure consistent and reliable production. These variations may include changes in temperature, humidity, and other environmental factors. concrete blocks machine The coping mechanisms are implemented to maintain the quality and efficiency of concrete block production.

Here are ways in which these machines handle variations in ambient conditions:

- Temperature Control Systems:

- Modern concrete block machines often incorporate temperature control systems to regulate the temperature of the concrete mix and the curing environment. This is crucial for ensuring proper setting and curing, especially in regions with fluctuating temperatures.

- Insulated Components:

- Key components of the concrete block machine, such as the mold and mixer, may be insulated to mitigate the impact of temperature variations. Insulation helps maintain consistent material properties and prevents rapid changes in the temperature of the concrete mix.

- Humidity Management:

- Humidity levels can affect the curing process and the consistency of the concrete mix. Some machines include features to manage humidity, such as covering the curing area or providing controlled ventilation to prevent excessive moisture loss.

- Adaptability to Seasonal Changes:

- Machines are designed to be adaptable to seasonal changes, considering factors like colder temperatures in winter or higher humidity in summer. This adaptability ensures that the machine can operate effectively throughout the year.

- Heating and Cooling Systems:

- In regions with extreme temperature variations, concrete block machines may be equipped with heating or cooling systems. These systems help maintain optimal conditions for the production process, regardless of external temperature fluctuations.

- Automated Adjustments:

- Some advanced machines feature automated systems that can make real-time adjustments based on ambient conditions. concrete blocks machines For example, the mixing time, vibration intensity, or curing duration can be adjusted automatically to account for changes in environmental factors.

- Weatherproof Design:

- Machines are often designed with weatherproof features to protect critical components from the elements. This is particularly important for outdoor installations where the machine may be exposed to rain, sunlight, or other weather conditions.

- Monitoring and Feedback Systems:

- Monitoring systems are integrated into the machine to provide real-time feedback on operating conditions. Operators can receive alerts or notifications if ambient conditions are outside the specified range, allowing for prompt adjustments.

- Material Preheating Systems:

- In cold climates, some concrete block machines may include material preheating systems. These systems warm up the raw materials, ensuring that the concrete mix remains within the optimal temperature range for production.

- Cooling Period Adjustments:

- During the curing phase, machines may be designed to adjust the duration of the cooling period based on ambient temperatures. This helps prevent premature drying or extended curing times, depending on the prevailing conditions.

- Sealed Mixing Chambers:

- The mixing chamber of the machine may be sealed to prevent moisture ingress or loss. This is important for maintaining the consistency of the concrete mix, especially in humid or rainy conditions.

- Preventive Maintenance Measures:

- Regular preventive maintenance is crucial to ensure that the machine remains in optimal condition despite varying ambient conditions. block concrete machine This includes checking and servicing components that may be affected by environmental factors.

By incorporating these features and strategies, concrete block machines can effectively cope with variations in ambient conditions, ensuring the stability and reliability of the block production process. It’s important for operators to follow manufacturer guidelines and best practices to maximize the machine’s performance in different environmental scenarios.