Concrete block machine is a new type of wall material – block brick, which is very in line with the current situation in my country. It is the most ideal, economical and practical alternative to clay bricks. It is a new type of wall material that has been vigorously promoted and used in my country in recent years. .

Introduction

It uses cement, sand, bean stone (or crushed cliff stone, pebbles or cinder, slag) as raw materials, it has the advantages of high hollowness, good quality, low cost, and not easy to weather. It does not use clay, does not compete with farmland, does not use fuel, and saves energy. It uses cliffs and rocks by relying on mountains, sand and gravel by rivers, and industrial waste residue by urban industrial and mining. It has abundant raw materials and a wide range of sources. Its production process is simple and the investment in building factories is low It has quick effects and can be mass-produced, suitable for both rural and urban areas. Using it not only Concrete Block Making Machine has advanced design, wide applicability, and easy construction and operation, but also can shorten the construction period and reduce the project cost. This kind of equipment is also known as the non-burning brick machine, which means that the produced cement bricks or hollow blocks do not need to be sintered, and can be left in the factory after a short period of drying. It can be said that the investment is small and the effect is quick. It is a popular industry for many investors to invest in.

Type

block machine

According to the different classification standards of concrete block machines, they can be divided into different types. The following are briefly described for your reference:

According to the type of bricks, it is divided into: standard bricks, hollow bricks and porous bricks

According to different forming principles, it is divided into: mechanical vibration type and hydraulic forming type

According to the degree of automation, it can be divided into: manual concrete block machine, semi-automatic concrete block machine and automatic concrete block machine

T

here are several representative models as follows:

Fixed hollow block forming machine

Mobile Hollow Core Block Making Machine

QT(4)6-15 type concrete block forming machine

QT (8, 10) 12-15 type concrete block forming machine

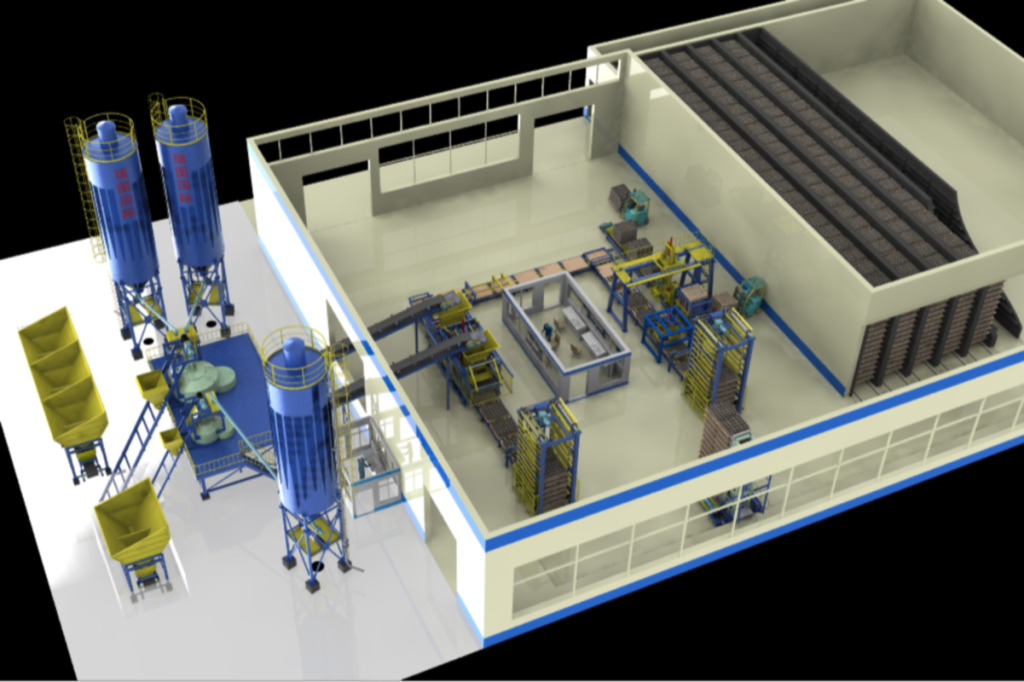

QTJ4-30 block production line

Features

The block machine equipment adopts closed belt conveying, and strictly controls the semi-storage volume of small materials, so that it can be used at any time, so as to prevent the concrete from liquefying in advance due to the influence of aftershocks, and ensure the strength of the product. The unique blanking and arch breaking device enables the material to be sent into the mold box quickly and evenly; the special double-end synthetic output vibration technology and the reasonable arrangement of the vibrator make the exciting force evenly distributed in the vibrating table. So as to ensure the consistency of product weight and strength. The overall structure of the block making machine is compact, the equipment is reasonable, and the rotating part adopts a mechanized device, which is accurate and reliable. Reduce labor intensity and improve production efficiency. Up and down pressure, directional vibration, variable frequency braking, to achieve high-density, high-strength molding effect. One machine has multiple functions, and it can produce block products of different shapes and specifications with different molds. The mechanical structure of each part is easy to observe, the operation is simple, the maintenance is convenient, and the failure is not easy to ensure the normal production operation….