Fire-resistant boards exhibit resistance to chemical corrosion and degradation due to several key factors:

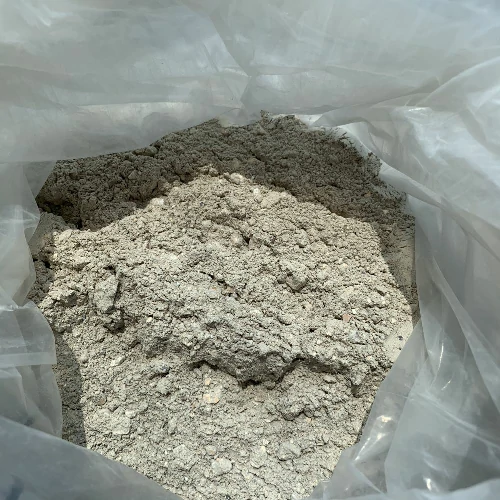

- Composition: Fire-resistant boards are typically made from inorganic materials such as cement, gypsum, or mineral wool. These materials are inherently resistant to chemical reactions and degradation, making them suitable for applications where exposure to corrosive substances is a concern.

- Non-Combustible Properties: Fire-resistant boards are designed to withstand high temperatures without burning or releasing harmful gases. Their non-combustible nature minimizes the risk of chemical reactions or degradation that may occur under extreme heat conditions.

- Surface Coatings: Some fire-resistant boards are coated with protective layers or additives that enhance their resistance to chemical corrosion. These coatings may include acrylic, silicone, or polymer-based materials that form a barrier against moisture, acids, alkalis, and other corrosive agents.

- Inertness: Fire-resistant boards are chemically inert, meaning they do not react with most chemicals or gases. This inertness prevents chemical corrosion and degradation, ensuring the structural integrity and longevity of the boards in corrosive environments.

- Physical Durability: Fire-resistant boards are durable and resistant to mechanical stress, impact, and abrasion. Their robust construction prevents physical damage that could compromise their chemical resistance and overall performance.

- Low Porosity: Fire-resistant boards have low porosity, meaning they have minimal pores or voids that could absorb moisture or chemical substances. This reduces the likelihood of chemical corrosion and degradation by limiting the penetration of corrosive agents into the board material.

- Testing and Certification: Fire-resistant boards undergo rigorous testing and certification to verify their chemical resistance properties. They are evaluated according to industry standards and regulations to ensure they meet specific performance criteria for resistance to chemical corrosion and degradation.

- Application-Specific Formulations: Manufacturers may develop specialized formulations of fire-resistant boards with enhanced chemical resistance properties for specific applications or environments. These formulations may incorporate additives or reinforcements that improve the boards’ ability to withstand exposure to corrosive substances.

Overall, fire-resistant boards are resistant to chemical corrosion and degradation due to their composition, non-combustible properties, surface coatings, inertness, physical durability, low porosity, testing and certification, and application-specific formulations. Their use provides reliable protection against chemical damage in a variety of industrial, commercial, and residential applications.