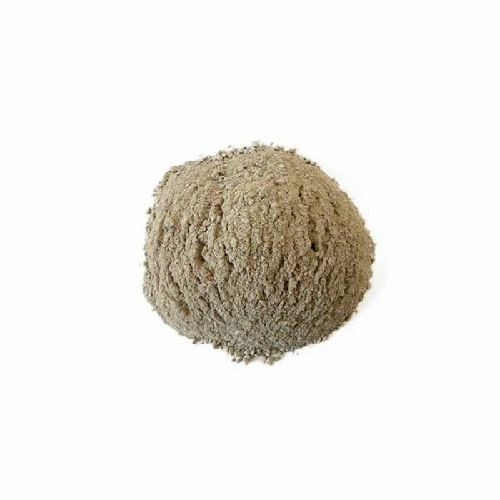

Gunning refractory castable, also known as gunning mix or gunning castable, is a type of refractory material that is specifically designed for application using a gunning machine or gunning equipment. It is a pre-mixed refractory composition that is pneumatically applied or “shot” onto a surface using high-pressure air. Gunning refractory castable is commonly used for repairing or lining refractory structures in various industrial applications, particularly in areas that are difficult to access or require quick installation.

The composition of gunning refractory castable may vary depending on the specific application and requirements, but it typically consists of refractory aggregates, bonding agents, additives, and sometimes fibers. The aggregates can include materials such as high-alumina, silica, magnesia, or other refractory minerals. The bonding agents are typically hydraulic binders, such as calcium aluminate cements, that provide strength and cohesion to the castable upon drying and firing.

Gunning refractory castable offers several advantages, including:

- Quick and Easy Installation: The gunning process allows for rapid installation of the refractory material, even in hard-to-reach areas or complex shapes. It enables efficient repairs and linings of refractory structures, reducing downtime in industrial operations.

- High Strength and Erosion Resistance: Gunning castable materials are designed to provide good strength, erosion resistance, and thermal stability in high-temperature environments. They can withstand thermal cycling, mechanical impact, and chemical attack.

- Versatility: Gunning refractory castables can be used in a wide range of applications, including the repair of ladles, furnaces, boilers, kilns, and other refractory-lined equipment in industries such as steelmaking, cement production, foundries, and petrochemicals.

- Flexibility: Gunning castables can conform to irregular shapes and surfaces, making them suitable for applications that require lining or patching refractory structures with complex geometries.

It’s important to note that proper installation techniques and curing procedures should be followed when applying gunning refractory castable to ensure optimal performance. Manufacturers and suppliers of gunning refractory castables can provide specific guidelines and recommendations for their products based on the application requirements and operating conditions.

Can you provide more information about the installation process of gunning refractory castable?

The installation process of gunning refractory castable typically involves the following steps:

- Surface Preparation: Before applying gunning refractory castable, the surface to be repaired or lined should be prepared properly. This may involve cleaning the surface to remove any loose materials, dust, or contaminants. It’s important to ensure that the surface is clean and free from any oils, greases, or other substances that could hinder adhesion.

- Mixing: Gunning refractory castable is typically supplied in a pre-mixed or ready-to-use form. However, it’s essential to follow the manufacturer’s instructions for mixing, if required. Some gunning castables may require a specific amount of water to be added to achieve the desired consistency. Mixing can be done using a paddle mixer or other suitable equipment.

- Equipment Setup: Set up the gunning equipment or gunning machine according to the manufacturer’s instructions. This may involve attaching the appropriate nozzle or gunning head to the equipment and ensuring that the air pressure and material flow rate are set correctly.

- Application: Start the gunning equipment and adjust the air pressure and material flow rate as needed. Position the nozzle or gunning head at the desired location and move it in a controlled manner to apply the gunning refractory castable onto the surface. The castable is pneumatically projected onto the surface using high-pressure air.

- Build-up and Consolidation: Apply successive layers of gunning castable to build up the desired thickness. Each layer should be applied evenly and compacted using the gunning equipment to ensure good adhesion and consolidation. The nozzle or gunning head should be moved in a controlled manner to cover the entire area.

- Curing: After the application of gunning refractory castable, it is necessary to allow the material to cure or dry. Follow the manufacturer’s recommendations regarding curing time and temperature. Curing can be done by air drying or using controlled heating, depending on the specific castable and application requirements.

- Finishing: Once the gunning castable has cured, it may require additional finishing or surface treatment, such as grinding, shotcreting, or coating with a protective layer, depending on the specific application and desired result.

It’s important to note that the installation process may vary depending on the specific gunning refractory castable product, manufacturer’s recommendations, and the requirements of the application. Always refer to the manufacturer’s instructions, technical data sheets, and safety guidelines for the particular castable being used to ensure proper installation and performance.