Filter cloth work by allowing certain particles or materials to pass through while retaining other particles.

Large surface area

Filter cloths have a porous, fibrous structure that provides a large surface area for particles to get trapped on. This allows them to filter out more particles.

Specific pore size

The pores in the filter cloth are of a specific size that will allow particles smaller than the pore size to pass through but retain larger particles. This allows them to achieve a certain level of filtration. Finer grade cloths have smaller pores for more efficient filtration.

Electrostatic charge

Some filter cloths develop an electrostatic charge that helps attract and retain certain types of particles based on charge. This can improve filtration efficiency for particles of specific sizes or materials.

Fiber materials

Different fiber materials can provide different filtration properties. Common fibers used include cotton, polyester, nylon, polypropylene, etc. The fiber type, density, and weave pattern all affect how well a cloth filters particles.

Wet strength

Some filter cloths are treated to remain stronger when wet. This allows them to continue filtering effectively without breaking down or tearing apart in wet conditions.

Pleating or layering

Pleating or layering multiple layers of filter cloth together improves filtration by providing more surface area and depth. Particles have a harder time passing through multiple layers.

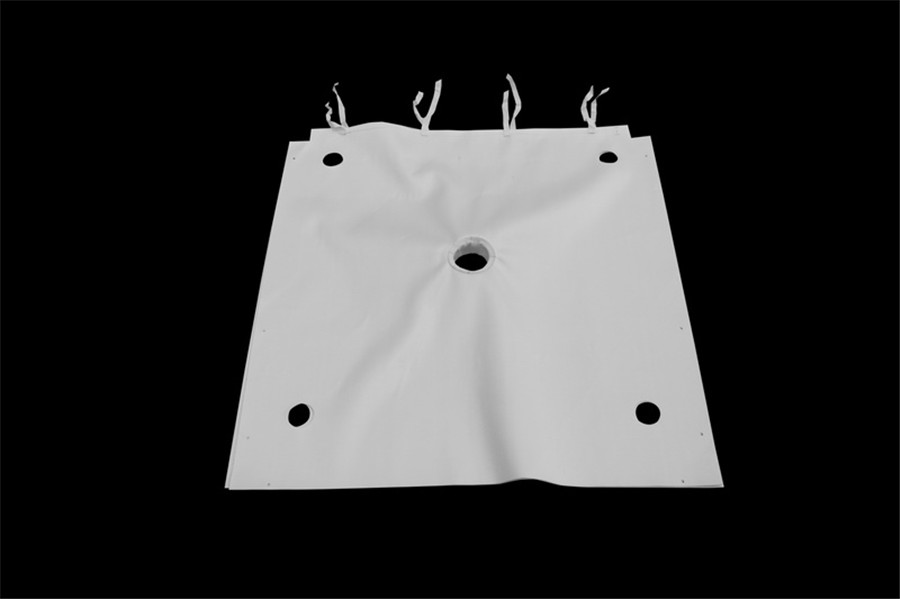

Built-in seal

Some cloths have a built-in seal or gasket around the edges to improve filtration by preventing unfiltered materials from passing through the sides or seams of the cloth.

That covers the basic highlights of how and why filter cloths are able to filter particles effectively.